Manufacture

From the processing of raw materials to constructing the product, there are numerous problems with footwear manufacturing. This content aims to cover health and safety issues and many of the social and environmental challenges directly linked to sourcing and manufacturing.

Health & Safety

Health and safety is linked to sustainability. Solving environmental issues e.g. the water pollution from leather tanneries, also improves the industry’s health and safety standards e.g. safer working conditions for leather tannery workers.

We’ve all heard the disaster stories associated with fast fashion sweatshops, such as the Rana Plaza factory collapse in April 2013, which cost 1,137 lives [1]. This was not the first tragedy of its kind, and many question whether enough has changed in regards to monitoring and enforcing workers’ rights since then. Footwear specific manufacture isn’t a topic of discussion, and yet similar factory accidents happen:

In 2012, 25 dead in a Pakistan shoe factory fire

In 2013, 2 dead and 6 injured in a Cambodian shoe factory collapse

In 2014, 16 dead in a Chinese shoe factory fire

In 2015, 72 dead in a Philippine shoe factory fire

In 2018, 10 dead in a Russia shoe factory fire

In 2021, 5 dead in a Bangladesh shoe factory fire

On 23rd Feb 2022, 3 dead and 40 injured in a Bangladesh shoe factory fire

It’s worth noting that the new legally biding International Accord on Health and Safety in the Garment and Textile Industry does not cover footwear manufacturers.

Explore the visual list below that highlights a number of health and safety problems: (click images for more information)

Labour Costs

To be able to keep up with the demand for cheap fashion, many workers are exploited in order to offer the best price.

Ignoring the need for safe working conditions means labour costs can be kept to a minimum. Employees see very little of the final shoe’s profit in exchange for their service. Both the Fashion Revolution campaign and The True Cost documentary highlight the issue of labour exploitation across the whole fast fashion industry - shoes included.

The NGO Labour Behind the Label investigated the footwear industry for their campaign, Change Your Shoes. To gain an understanding of the kind of wages that workers can expect, here are just a few examples worth noting:

“In Ambur, women homeworkers are paid less than 10 pence a pair, for stitching the uppers of shoes sold in the UK for prices between £40 and £100.” [2]

“The maximum Jyoti can stitch in one day is 16 pairs, earning her under £1.60. Although cost of living differs, this is simply not enough to cover her basic needs. A kilo of rice alone costs her 43 pence. Jyoti earns well below a minimum wage, let alone a living wage.”

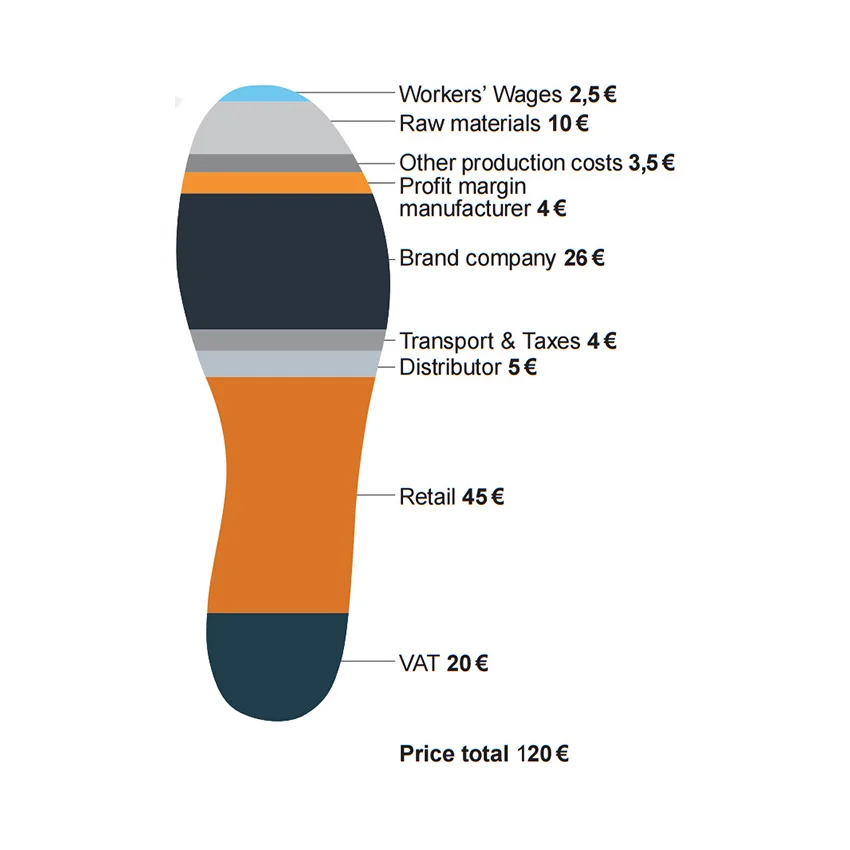

The chart to the left shows that workers’ wages make up the smallest proportion in the final price of the shoe. The largest proportions go towards the brand (21%) and the retailer (37.5%). [3]

CHILD LABOUR & FORCED LABOUR

The International Labour Affairs Bureau (ILAB) maintains a list of goods and their source countries which it has reason to believe are produced by child labour or forced labour in violation of international standards.

ILAB maintains the List primarily to raise public awareness about forced labour and child labour to promote efforts to combat them; it is not intended to be punitive, but rather to serve as a catalyst for more strategic and focused coordination and collaboration among those working to address these problems.

Publication of the List has resulted in new opportunities for ILAB to engage with foreign governments to combat forced labour and child labour. It is also a valuable resource for researchers, advocacy organizations and companies wishing to carry out risk assessments and engage in due diligence on labour rights in their supply chains.

It’s worth noting that the ILAB 2020 report lists the following countries to be a potential risk of child labour specifically in footwear manufacturing: Bangladesh, Brazil, India, Indonesia, Turkey, and Vietnam, whilst China is listed as a potential forced labour country under footwear as well.

Environmental Impact

One of the main environmental impacts of shoes come from sourcing and manufacturing. Energy forms, energy efficiency, use of chemicals, waste disposal and water treatment are things that have direct effects on the environment.

Statistic from (Journal of Cleaner Production, 2013)

CARBON EMISSIONS

“A single shoe can contain 65 discrete parts that require 360 processing steps for assembly.” [4] A study published in Elsevier suggests that the manufacture process accounts for 68% of the carbon footprint of a running shoe, with materials being the second biggest element. [4] The amount of energy it takes to produce one shoe depends on the materials, the manufacturing method and the structure of the shoe. One example of a more environmentally friendly shoe is one made using fabric that has been dyed with waterless methods.

The source of energy and energy efficiency should also be considered. 88% of the world’s footwear is produced in Asian countries [5] like China, where coal and other unsustainable energy sources are still widely used. [6] Luckily the interest of developing renewable energy forms is on the rise. For example Portugal, one of the main footwear producers in Europe [7], ran on 79.5% renewable energy during Q1 in 2021.

DEFORESTATION

New research into the footwear and fashion industry’s complex global supply chains shows that many large brands are linked to deforestation in the Amazon rainforest.

The study released in November 2021 was conducted by Stand.earth and Slow Factory. They analysed nearly 500,000 rows of customs data and found multiple connections between brands to certain sources of hides, tanneries and other companies involved in the production of leather.

The findings are surprising, in part because a number of the brands surveyed have previously announced policies to untangle themselves from actors along the supply chain that contribute to deforestation; which suggests that with the best of intentions its almost impossible to control the supply chain due to its complexity. More rigorous in-depth traceability practices are required to ensure safe and ethical resources, especially with leather sourcing - since intensive cattle farming is the single largest driver of deforestation. This is by no means a new trend, Greenpeace have previously published Slaughtering the Amazon report back in 2009, following three years of investigations.

POLLUTION

A responsible use of chemicals is needed to shift us towards a more environmentally friendly footwear manufacturing. Leather tanning, petroleum oil extraction (for rubber and plastic components) and solvent-based glues contribute to environmental damage through acts like poor water treatment, the destruction of natural habitats and air pollution. Just to give one example, the Buriganga river that runs across the biggest tannery district in Bangladesh was declared biologically dead as no aquatic life could possibly survive in the contaminated water. But there are ways to minimise or avoid these problems, check our list of solutions below.

WASTE

Waste is also of huge concern, considering that 1.2 million tonnes of post-consumer shoe waste are produced each year. [7] The choice of manufacture methods (as well as the material selection) affects what happens after a shoe’s useful life. The knock-on effects of this decision should be addressed earlier on in the lifecycle, rather than having to solve the bigger problem of growing landfills later on. Interested in this subject? We’ve discussed the post-consumer life of a shoe in more depth over here.

Solutions

Implement best H&S practices in shoe factories to minimise the risk of fire.

Adhere to best-practice or internationally recognised set of labour standards to protect workers within the supply chain, such as Fair Wear, or Ethical Trading Initiative.

Consider regular ethical standards audits to better manage your social and environmental performance with third party providers such as Sedex, or Qima - especially if you produce in a country that is listed as a potential risk of child labour or forced labour under ILAB.

Clearly, leather is a problem. So either avoid the use of leather altogether by researching our suggestions for vegan alternative leather like Piñatex™, or…

Clean up your existing leather production process by:

Ensuring full cooperation with REACH regulations by following up on your positioning in the legally required REACH dossier.

Choose chrome-free vegetable tanned leathers such as Wet-Green or Rhubarb Leather.

Search for Gold rated and audited tanneries through The Leather Working Group, and also validate full traceability of hides source to ensure that they don’t contribute to deforestation.

Support the wellbeing of factory workers by:

Considering the effect the shoe’s design has and how it can be manufactured, and using alternative construction methods as a starting point for answering the design brief, for example this glueless construction by Clarks Origin

Switch from highly flammable and toxic solvent-based glues to safer water-based glues (scroll down to JOINING METHDS). In our experience this switch is likely to result in higher productivity (thanks to staff being healthier and more alert), which should compensate for the slower drying process.

Introducing a higher price point and passing this on through fair wages.

Consider all stages of the lifecycle of your shoes, including disposal. Analyse your products through in-house exercises e.g. the LiDS wheel or software e.g. LCA Calculator or use independent assessments like Positive Luxury or Ethical Company Organisation to publicly declare your excellent standard of conducting business!

Avoid using harmful solvent-based glues by either switching to water-based adhesives, or use glueless construction like Proef have done with their Loper shoes. We have a growing list of case studies if you’re keen to see more examples of this kind of thinking.